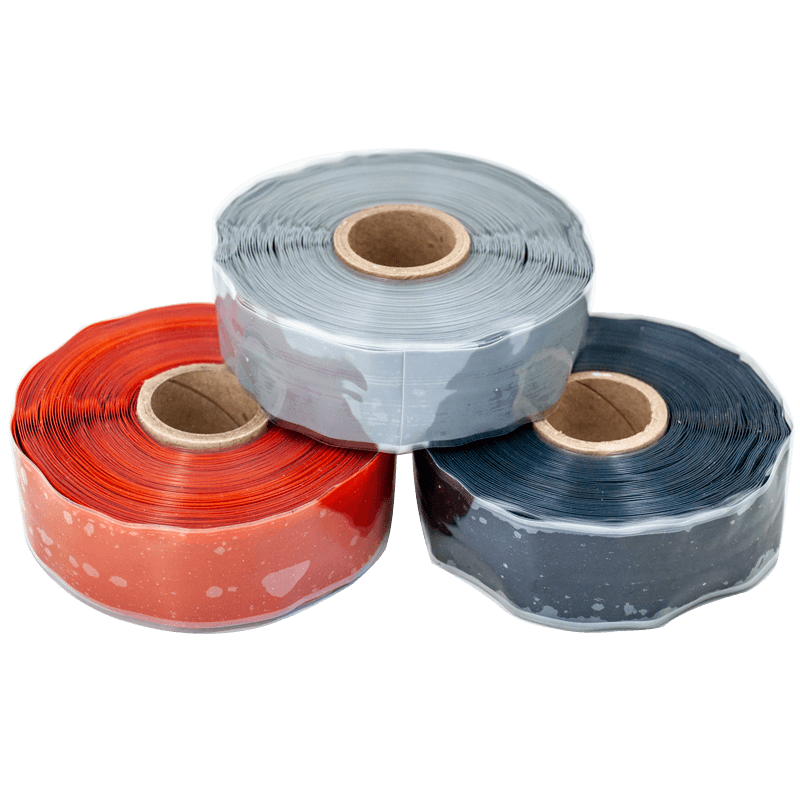

Description

Our 160 Series Silicone Rubber tape is for indoor or outdoor use, to protect splices, connections and end cables from contamination such as oil, dust, moisture, weather, sunlight, etc. Excellent electric strength, moisture and chemical resistance and conformability. Used wherever the ultimate in conformability is required to provide problem free insulating over irregular surfaces or where protection is sought from contaminated environments. Can be used for any type of emergency hose repair, including exhaust lines, marine hose repairs, automotive hose repairs, plumbing repairs, replacement for heat shrinkable tubing. Excellent replacement for electrical tape on boats.

Features

- Self-bonding silicone rubber wrap which readily adheres to itself when wrapped under tension. Fuses to form a homogeneous mass within 24 hours at room temperature. Applying heat after wrapping will shorten curing time.

- No adhesive; tape leaves no sticky residue.

- Clear polyethylene liner protects the tape from blocking.

- Capable of withstanding temperature variations from –65oF to +500o

- Excellent dielectric properties.

- UV Resistant EXCELLENT – suitable for extreme conditions – provides longevity in field 5 years and longer (depending upon exposure conditions)

- Chemical resistant.

- Resistant to salt water, sunlight, and fuels.

- Will not deteriorate like butyl rubbers, neoprene.

- Produced in two configurations – triangular and rectangular. Triangular, is thicker in the middle and tapers downward at each side with a line running along the apex of the tape. This acts as a guideline for succeeding wraps producing a uniform thickness layer.

- 20 mil Rectangular version Meets MIL Spec A-A-59163 Type 1 (formerly MIL-1-46852C).

- 20 mil Triangular version Meets MIL Spec A-A-59163 Type II (formerly MIL-1-46852C).

| Item # | Config | Color | Thickness | Size | Units / Case |

|---|---|---|---|---|---|

| 16120 | Triangular | Orange/Red | 20 mil | 1″ (25.4mm) x 30 ft | 48 / case – Bulk |

| 16127 | Rectangular | Gray | 12 mil | 1″ (25.4mm) x 30 ft | 48 / case – Bulk |

| 16012 | Rectangular | Gray | 20 mil | 1″ (25.4mm) x 30 ft | 48 / case – Bulk |

| 164109R | Rectangular | Black | 20 mil | 1″ (25.4mm) x 30 ft | 48 / case – Bulk |

| 164209R | Rectangular | Black | 20 mil | 2″ (50.8mm) x 30 ft | 24 / case – Bulk |