Description

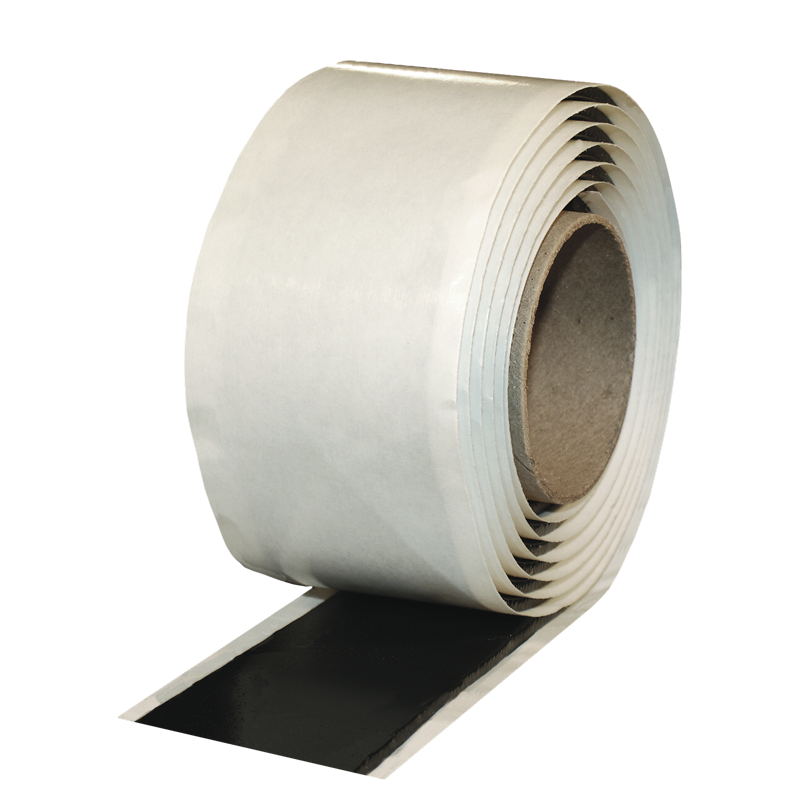

Our 125 Series electrical filler tape is a cross-linked butyl and polyisoprene based elastomeric insulating compound in 1/8” thick tape form designed for quick, cost effective insulation buildups.

The #125 is a self-amalgamating compound that can be readily compressed and molded by hand to conform to irregular shapes and contours. It is to be used in conjunction with other insulating tapes for complete installation.

Features

• For rapid insulation build-up thru 5 KV.

• Builds up insulation quickly.

• Self-amalgamates into a solid flexible mass.

• Will not corrode copper or aluminum.

• Non-oxidizing, ozone resistant, and water-resistant.

Applications

Can be used as a primary insulation for connections up to 5 KV in conjunction with high voltage insulating tape or vinyl plastic electrical tape. The #125 is ideal for covering split-bolt connections, and sealing switchgear and transformer terminals.

| Item # |

Roll Size |

Units / Case |

Case Size |

Case Weight |

| 42015 |

1.5″ (38 mm) x 60 in |

36 / case – Cello Wrapped |

n/a |

25 lbs |

Technical & Consumer Data

Physical Properties

Color: Black

Thickness: 0.125 in.

Elongation: 1000 %

Heat Resistance: 95°C

Operating Temperature: 80°C

Emergency Overload Temperature: 95°C

Separator: Pass

Water Absorption: 0.13 %

Copper Corrosion: None

Dielectric Strength: 250 volts / mil

Flash Point (TCC): >450°F

Odor: Low odor

RESISTANCE TO: Weather, water, water vapor, acidic or basic soil conditions. (5% solution of HCl, sulfuric acid, and sodium hydroxide).

EFFECTED BY: Oil, carbon tech. Naphtha, mineral spirits and gasoline.

LIFE EXPECTANCY: Indefinite, actual weather exposure and accelerated testing indicates that hardening, shrinking, cracking, drying, or loss of adhesion will not occur. Excellent resistance to degradation caused by thermal cycling.

The physical and performance characteristics shown are averages obtained from tests recommended by ASTM, government agencies or our own procedures. A particular roll may vary slightly from these averages and it is recommended that the purchaser determine the suitability for his own purpose.